There are only a few countries that are carbon-negative, and they are all small. Only one has been officially certified, and that is the Kingdom of Bhutan. It offsets four times as much carbon as its economy emits.

Most materials have a positive carbon footprint, meaning that the harvesting, extraction, manufacture, and shipping related to them releases carbon, or in other words, that they contribute to the climate crisis. Steel, concrete, and aluminum are among the worst offenders.

The building sector has been a major contributor to carbon emissions. Cement, the binder component of concrete, accounts for 8 percent of global carbon emissions, or 25 percent of all industrial emissions. One ton of cement emits almost a ton (0.9) of carbon. If we could populate an imaginary country with all the cement manufactured every year, it would be the third largest carbon-emitting country, trailing only the U.S. and China.

Universities and private companies are researching ways to reduce concrete’s carbon impact. One company, Partanna Global, has developed a concrete that minimizes CO2 emissions during manufacture while offsetting these few emissions by absorbing carbon from the atmosphere during the curing process. According to the company, it is as versatile and affordable as traditional concrete, and in addition, it is stronger and more durable.

Of course, the company does not reveal its proprietary formulas, but does say it uses steel slag, a biproduct when iron ore is turned into steel. It also uses desalination waste, a chemical left behind when brine or saline water is made potable. This alkaline, calcium-laced water saturates the slag during formulation, creating reactive compounds that absorb CO2 into the concrete mix to become the binding agent. Moreover, these reactive compounds continue absorbing carbon from the air throughout the life of the concrete.

Since cement, a key component of concrete, is ubiquitous in buildings, Partanna, by developing a carbon-negative concrete, has been able to easily take the next step and create carbon-negative homes. They have built their first negative homes in the Bahamas and have secured an agreement with the government to build 1,000 more. Each of these modest 1,250-square-foot homes will capture 182 tons of CO2 from the air, the equivalent to the annual carbon absorbed by more than 5,000 mature trees.

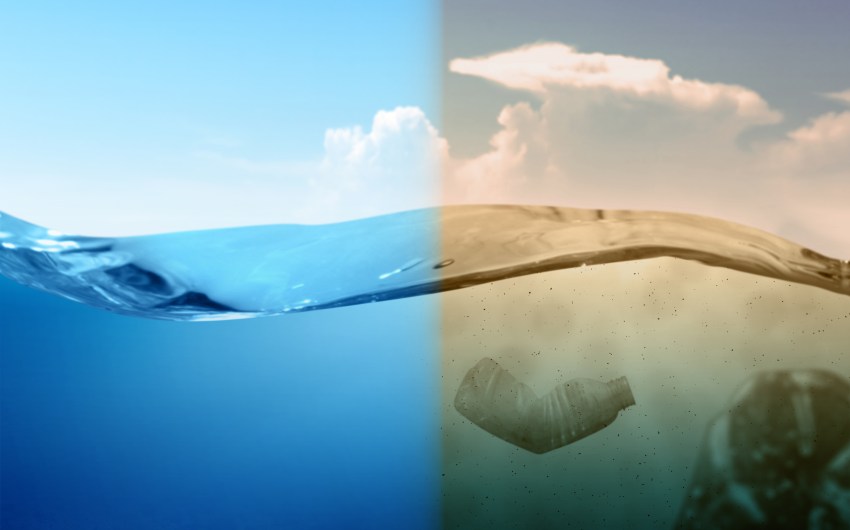

Another factor that helped convince the Bahamas to commit to these new homes is that the concrete gets stronger when exposed to seawater, whereas traditional concrete is weakened by this exposure. This makes it ideal for low-lying communities faced with the threat of sea rise and storm surges.

Carbon-negative concrete would shift the building industry from being one of the biggest contributors to climate change to helping heal the planet, while recycling waste products into the concrete.

Premier Events

Fri, Jan 09

5:30 PM

Santa Barbara

Intention Setting & Candle Making Workshop

Sun, Jan 11

3:00 PM

Santa Barbara

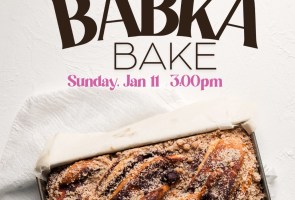

Mega Babka Bake

Fri, Jan 23

5:00 PM

Santa Barbara

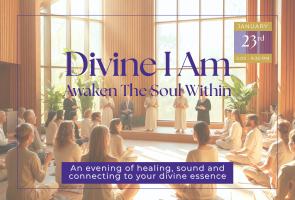

Divine I Am Retreat

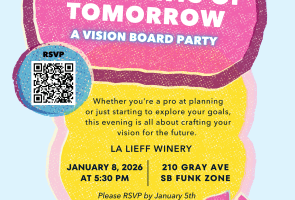

Thu, Jan 08

5:30 PM

Santa Barbara

Blueprints of Tomorrow (2026)

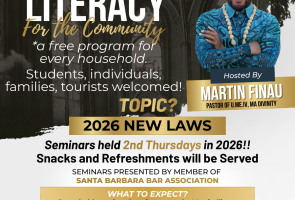

Thu, Jan 08

6:00 PM

Isla Vista

Legal Literacy for the Community

Thu, Jan 08

7:30 PM

Santa Barbara

Music Academy: Lark, Roman & Meyer Trio

Fri, Jan 09

8:00 AM

Santa Barbara

Herman’s Hermits’ Peter Noone: A Benefit Concert for Notes For Notes

Fri, Jan 09

6:00 PM

Santa Barbara

Ancestral Materials & Modernism

Fri, Jan 09

6:00 PM

Montecito

Raising Our Light – 1/9 Debris Flow Remembrance

Fri, Jan 09

7:00 PM

Santa Barbara

Barrel Room Sessions ~ Will Breman 1.9.26

Sat, Jan 10

9:00 AM

Santa Barbara

Rose Pruning Day | Mission Historical Park

Sat, Jan 10

7:00 PM

Santa Barbara

Konrad Kono – Live in Concert

Sat, Jan 10

8:00 PM

Santa Barbara

SB Improv: The Great Cornadoes Bake-Off

Fri, Jan 09 5:30 PM

Santa Barbara

Intention Setting & Candle Making Workshop

Sun, Jan 11 3:00 PM

Santa Barbara

Mega Babka Bake

Fri, Jan 23 5:00 PM

Santa Barbara

Divine I Am Retreat

Thu, Jan 08 5:30 PM

Santa Barbara

Blueprints of Tomorrow (2026)

Thu, Jan 08 6:00 PM

Isla Vista

Legal Literacy for the Community

Thu, Jan 08 7:30 PM

Santa Barbara

Music Academy: Lark, Roman & Meyer Trio

Fri, Jan 09 8:00 AM

Santa Barbara

Herman’s Hermits’ Peter Noone: A Benefit Concert for Notes For Notes

Fri, Jan 09 6:00 PM

Santa Barbara

Ancestral Materials & Modernism

Fri, Jan 09 6:00 PM

Montecito

Raising Our Light – 1/9 Debris Flow Remembrance

Fri, Jan 09 7:00 PM

Santa Barbara

Barrel Room Sessions ~ Will Breman 1.9.26

Sat, Jan 10 9:00 AM

Santa Barbara

Rose Pruning Day | Mission Historical Park

Sat, Jan 10 7:00 PM

Santa Barbara

Konrad Kono – Live in Concert

Sat, Jan 10 8:00 PM

Santa Barbara