Nano Scientists Make Face Shields for Cottage

UCSB Workshop Takes on Shortage of Personal Protective Gear

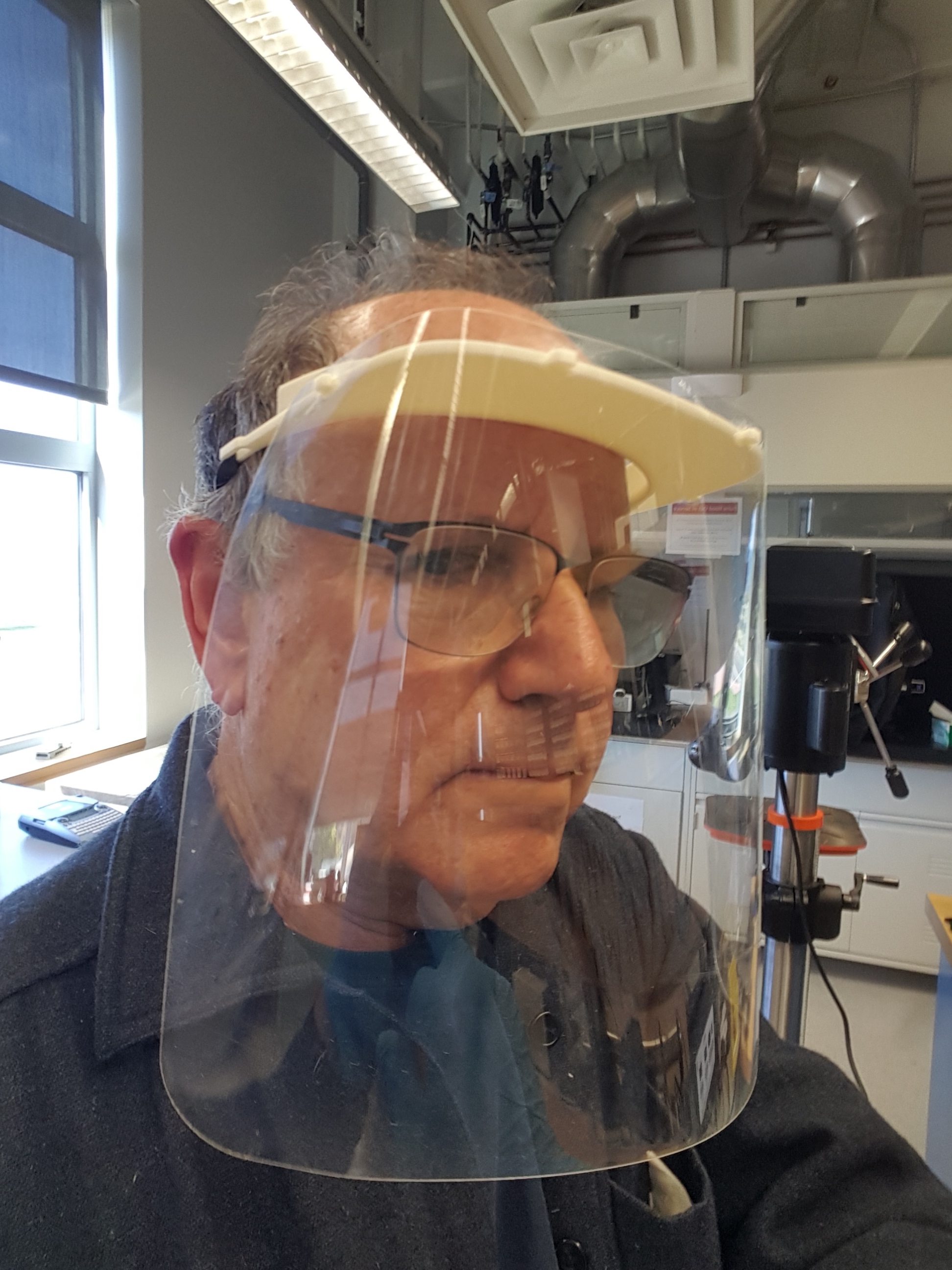

Even David Bothman’s mother thought he should jump into the homemade face-shield industry. Home in Bothman’s case, however, is a lab and a workshop at the California NanoSystems Institute (CNSI) on the UC Santa Barbara campus.

When Cottage Health officials began to run low on protective gear, Bothman and his cohort began cranking them out, using the nanosystems’ shops’ 3D printers. They’ve been spitting out plastic frames and are gearing up for more projects and volunteers. The Independent contacted him to learn more.

This is such a great idea. Who hatched it?

People all over the world who have access to tools are making personal protective equipment (PPE) for hospitals. Early this week, several faculty who are familiar with the tools in the Innovation Workshop at the California NanoSystems Institute (CNSI) at UCSB sent me information about several different products. My mother even sent an article from England about home-made protective face shields. That’s the design that we’re producing — it’s best suited to our 3D printers.

I think that everyone would like to help. We can all lend a hand in our neighborhood, but we don’t have the specialized knowledge needed to help at the hospital. Making stuff for the hospital is what I can do. I’m impressed with all of the ideas being shared.

How many people are involved, and how many are you all making a day?

The group is expanding, though we’re all working independently. Right now there are four of us on campus working on face shields, and several people in town who have 3D printers at home have volunteered to make parts.

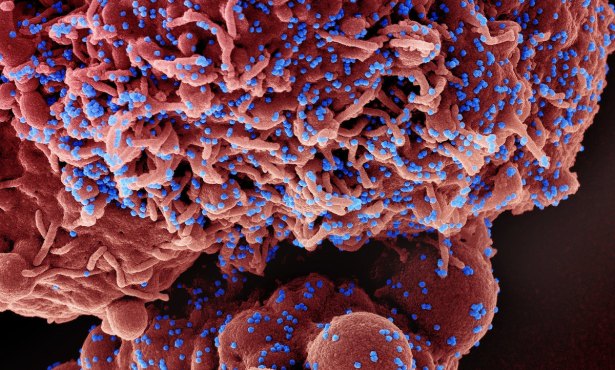

Our lab can make about 24 protective shields each day. These provide an additional layer of protection for health-care providers, in addition to goggles and the N95 masks that they wear around infected patients.

Who do you give them to?

Most of the masks are destined for Cottage hospital. Professor Eric McFarland in the Chemical Engineering Department here is the liaison with the hospital. He’s also an emergency-room physician, so he’s been an invaluable resource for connecting local industry, the UCSB community, and the hospital to keep everyone focused on making the items that Cottage needs. We’re also making masks for use around the campus.

What kind of masks do they need the most?

I really don’t have the big picture of what Cottage needs. Making face shields is what we can do now. We may help make holders for HEPA filters [for very fine particles] in the future.

How expensive are they to make?

Our face shields cost about $10 in materials each. The labor is all volunteered.

When you’re not dragooned into volunteer labor for medical supplies, what do you do at the university during less drastic times?

The main focus of my job is running a couple of labs at CNSI — the Innovation Workshop and the Microfluidics Lab — where campus users build scientific instruments and prototypes of their own inventions. I used to teach mechanical engineering design and manufacturing, and have always liked building things. Every day I get to collaborate with students, staff, and faculty to bring their ideas to fruition. I love it.

At the Santa Barbara Independent, our staff continues to cover every aspect of the COVID-19 pandemic. Support the important work we do by making a