UC Santa Barbara Undergrads Design Innovative Weight Workout Machine That’s Accessible to People Who Use Wheelchairs

Engineering Capstone Project Teams with Nonprofit Beyond Disabilities

This story originally appeared in UC Santa Barbara’s ‘The Current.’

Most gym equipment isn’t that accessible for people with disabilities. Steve Ferreira knows this all too well. Born with cerebral palsy, a condition that makes it hard for him to move and speak, he is a fitness fanatic and winner of multiple para-athletics awards. He gets around in a high-tech motorized wheelchair.

Ferreira has a powerful upper body and likes to work out, but the barriers to doing so at the gym can be nearly insurmountable. He doesn’t let that stop him, and he doesn’t want it to stop others, either. An advocate for people with disabilities who has 50,000 followers on TikTok, he runs a nonprofit, Beyond Disabilities, that provides support to those who want to overcome any disability-related limitations they might face.

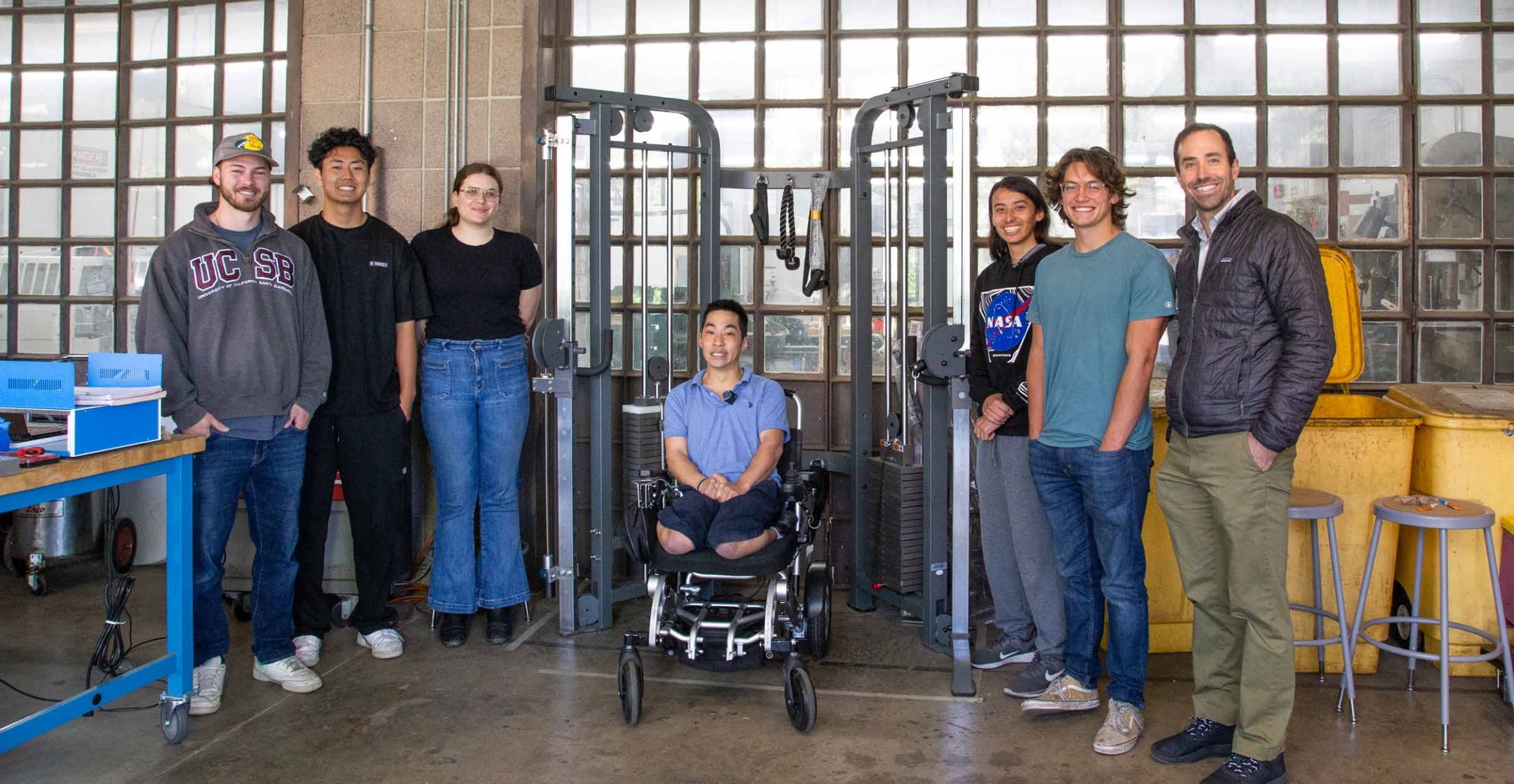

And now, in partnership with UC Santa Barbara, he’s working on a weight machine that will be accessible to everyone. Five senior undergraduate students in the Mechanical Engineering Department — Joseph Byun, Janna Crocker, Cannon Crow, James Freda, and Carlos Rivera — teamed with Ferreira to adapt a standard pulley-and-cable weight machine to be accessible to people with disabilities, including those who use wheelchairs. The innovative capstone project was presented along with 25 others at the 2023 Engineering Capstone Expo on June 9.

The team focused on three features that make a standard cable exercise system unusable for wheelchair users, especially those who have hand-dexterity issues: weight stacks are too low to access while in a wheelchair; selecting a weight might be impossible for a person with limited dexterity; and the height adjustment of the pulley is too cumbersome to adjust and may be out of reach. The students are working with Ferreira on a design change to address all three problems, making the weight stack reside in an easily accessible height, guiding weight selection, and integrating a remote-control keypad to move the pulley up and down electronically. Their project, BDS (Beyond Disability Systems) Functional Trainer, is sponsored by Beyond Disabilities and supported by capstone course instructor Tyler Susko, an associate teaching professor.

“We’re taking a couple of features that people with disabilities, and specifically those in wheelchairs, might have trouble with,” said Susko, vice chair of undergraduate mechanical engineering, who wrote his Ph.D. dissertation for Massachusetts Institute of Technology on rehabilitation robotics. Every year, among 17 total projects, Susko includes two capstones related to serving those with disabilities. “We met with Steve to try to figure out the different things that he and others in wheelchairs might have trouble with.”

Ferreira’s take on fitness — and on everything — is that he is essentially no different from anyone else. “My wants and needs are like those of other people,” he said. “It may take me a little longer to do things, and I may need things to be adapted, but it’s important that people with disabilities have the same experiences as other people.”

While Ferreira and others with disabilities face daily challenges, such as doors that lack automatic openers or single steps without a wheelchair ramp, they also encounter less-visible barriers, or “attitudinal obstacles.” “Society tends to focus on what people with disabilities cannot do, rather than our accomplishments,” he said. “It just gives me more motivation to accomplish my goals.”

Fortunately, Ferreira noted, “There are people who share my vision, and these are the people who are developing tools for people with disabilities.” He counts Susko and the capstone students among them. “There is a lot more work that needs to be done, but this has been a great project.”

In conceiving capstone projects, which Susko does every year after spending the summer pitching companies and other organizations to sponsor them, he has to make sure that they are appropriate for students and the time and resources they have.

“If you’re going to design something that is mass-marketed, like a car, which has been refined over a hundred years, it’s really hard to find a point of entry unless you’re a huge company,” he said. “But the disability space is relatively small and there are not many people thinking about it, so it’s easy to find something to do. People with disabilities all have unique challenges, unique problems that haven’t been addressed, and the solutions are usually simple. It’s much easier to find a point of entry for students.”

Students, meanwhile, take away valuable skills and lessons from the experience, including how to shift gears when things don’t go according to plan. “I think the most important thing I’ve learned through this project is that design is a process,” said Janna Crocker, who had ownership of the software, the electrical components, and the technical writing for the BDS project. “It’s easy to get into the mindset of thinking a solution will work because it sounds perfect, but most of the engineering happens in the debugging phase, when a theoretically perfect solution needs a little more work. Preparing for this and being able to keep working toward solutions instead of getting frustrated by design changes and debugging are incredibly important engineering skills that I’ll definitely take with me after I graduate.”

The project was highly open-ended to start, she explained. “Our goal initially was very broad: to make working out more accessible for Steve,” said Crocker, who will work as a spacecraft systems engineer at satellite startup Umbra Space after graduating. “That was a great starting point to brainstorm from and gave us a lot of space to think of different parts of working out that we could make more accessible. It’s a huge problem, with so many different specific issues we could have tackled. We ended up narrowing our scope to focus on one machine Steve frequently uses.”

Washington-based Ferreira visited UC Santa Barbara in May, meeting the team in the mechanical engineering machine shop where students work on their capstone projects. He also tried the then-unfinished adaptive weight machine, describing it as “a great start to the project that, with some additional research and development, should be a great product.”

“It was good to finally meet all of the team and to see the machine in person rather than on the computer screen,” he said at the time. “My hope is that this project creates awareness for the fitness needs of people with disabilities, and I envision gyms incorporating similar workout equipment in the near future.”

Susko agreed, saying that the adaptable weight machine “has start-up written all over it.” While none of the students on the team plan to pursue that path, he sees it as a multi-year project and hopes that future students might take the technology in that direction. “We’ll see if we can get someone interested enough,” he said, “maybe a commercial fitness equipment producer, so that it eventually becomes a thing in gyms.”