3-D Printing for You and Me

Mission Street Manufacturing Making Three-Dimensional Printers Affordable and Easy-to-Use

Right now, inside what appears to be an otherwise residential Craftsman bungalow on Santa Barbara’s Westside, a team of young technology wizards is hammering away at making history. In the living room, where the walls are covered in butcher paper featuring scribbles of recent brainstorming sessions, a handful of software designers huddle around their computers, barely even looking up to acknowledge visitors.

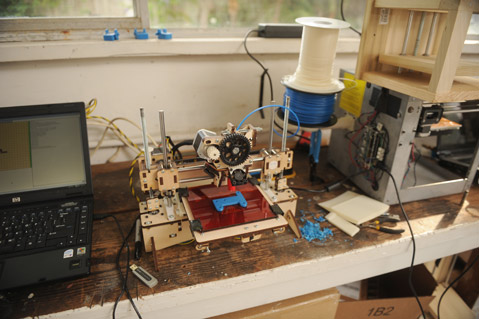

Out back in the garage, next to the Astroturf putting green and Airstream trailer that’s become home for the team leaders, another handful of hardware experts intently watch machines as they build three-dimensional plastic objects like poker chips and coasters. It is a typical afternoon at Mission Street Manufacturing, which has been furiously working all summer to change the face of 3-D printing, one of the fastest-growing sectors of the high-tech hardware market.

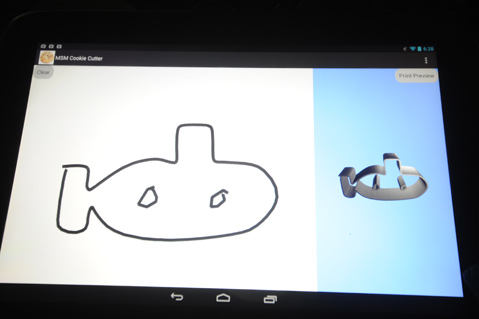

“We want to bring 3-D printing to a whole new group of people,” said Brian Jaffe, a 29-year-old Navy veteran originally from Oregon who attended one year of business school at MIT before moving into the Mission Street home he had purchased as an investment years ago. In early June, he started assembling a small staff and interns from UCSB and Cal Poly with backgrounds in both developing software (to make easy-to-use applications) and industrial design (to build a better printer). “We’re focusing on K-12 education,” said Jaffe, who intends to dramatically bring down the price of the printers and make the user interface simple enough for kids and non-tech-savvy teachers to use. “We’re developing the whole experience.”

Currently, as seen in Jaffe’s garage, the 3-D printing experience ranges from sleekly designed, consumer-friendly models (which are slow and expensive, costing far more than $1,000) to the much more affordable yet rather clunky printers that come in kits and require steady hands to build and constant vigilance to keep operational. The existing apps to control the printers, meanwhile, also require near-expert levels of technical computer-design skills.

Jaffe’s vision is to improve on all these fronts — offering specialized design templates that focus on science, art, and other school-related topics — and do so with breakneck speed. “Quick is the name of the game,” said Jaffe, who added that another emergent 3-D printing company was recently bought for $600 million. “This industry is just moving so fast.” On Sunday, Jaffe’s team will be unveiling an early prototype at the Santa Barbara Museum of Natural History’s Tinker Fest and should have final designs by the end of summer. He hopes to have the printers in production by early next year.

Jaffe is certain that the printers will be an immediate hit in classrooms, introducing kids at early ages to principles of design, art, and even science — imagine building molecular models with the printers, for instance. “I’d love to go back in time and give this to me as a kid because I would have loved it,” said Jaffe, who compares it to the toothpick bridge projects of yesteryear. “What if we really made it about the design aspect — not just who can put more glue on toothpicks?”

If successful in schools, Mission Street Manufacturing will likely make these printers much more common in everyday homes, too. “Ideally, we’d like to hit the price of an iPad,” said Jaffe, which would make it affordable to many middle-class families, as well. “Kids absolutely love 3-D printing,” said Jaffe. “It’s like the next closest thing to magic. It’s so neat to see their reactions.”

He also sees it as the “ultimate empowerment” tool for all ages. Said Jaffe, “You can make anything that you can think of.”

4•1•1

See missionst.com or check out Mission Street Manufacturing at the S.B. Museum of Natural History’s Tinker Fest this Sunday, July 21, 10 a.m.-4 p.m. See sbnature.org.