Pipeline Photos Begin to Tell Story of Refugio Oil Spill

Operating Line 901 was Risky Business, Says Disaster Investigator

While there are still many questions to be answered about the human behavior that led to the continuing operation of an extremely corroded oil pipeline running through a highly sensitive environment adjacent to the Pacific Ocean, photos released by the pipeline operator are helping to fill in the picture on matters of a technical nature.

To ascertain exactly how, The Santa Barbara Independent caught up with Robert Bea, a professor emeritus of civil engineering at UC Berkeley sometimes dubbed the “master of disaster” because he has studied such iconic catastrophes as the Columbia space shuttle’s failed reentry, the Exxon Valdez spill, the BP Deepwater Horizon blowout, and the failing of the New Orleans levees after Hurricane Katrina.

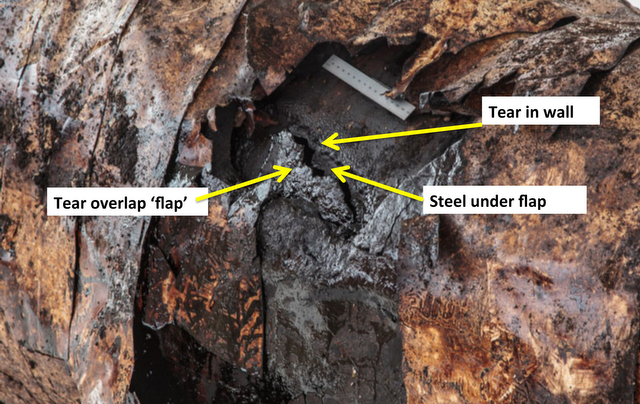

The most pressing question is how a smart pig device that measures pipe safety data – or those who interpret the data – could detect 45 percent corrosion of the busted pipe just weeks before the spill when metallurgy tests afterwards revealed up to 82 percent reduction in pipe wall thickness. “Even a dumb pig would be able to detect this amount and extent of corrosion,” quipped Bea. But after studying photos of the ruptured pipe, Bea surmised that delaminated steel could have given a false impression of the pipe’s diameter. In the accompanying photo annotated by Bea, he points out a delaminated flap extending under the rupture.

He also explained that the broken pipeline was buried in a low spot, which would collect winter rain. Factor in the heat of the pipeline (120 degrees Fahrenheit) and the fact that the ground in this area is already highly corrosive, said Bea, a former Shell executive who has lived in Bakersfield, and it’s no surprise that this particular section broke. Such conditions would induce both internal and external corrosion, the latter less detectable by a pig.

By Bea’s calculations, even if the pipeline were at 40 percent corrosion, loss of containment would be expected at 700 pounds per square inch (psi). Relative to atmospheric pressure, the normal operating pressure of the line was 650 psi. According to a corrective action order issued by the Pipeline and Hazardous Waste Materials Safety Administration, pipe operator Plains All-American reported a pressure of 700 psi immediately prior to the spill.

“The pressure spike is what probably precipitated the burst at the flap section,” said Bea. “That it didn’t burst earlier is a tribute to the steel, not appropriate risk management.”

The location of the spill is also significant for environmental, social, and historical reasons that would not go unnoticed by a student of disasters. In such a pristine area so close to the 1969 Union Oil platform blowout that changed the course of environmental history, said Bea, “You need to be sure that your containment is very stringent. You cannot tolerate [even] a 45 percent loss and have appropriate management of likelihood of spilling that oil. That does not make sense.”

Corrosion has long been an issue on the pipeline. According to the corrective action order, Plains excavated 13 and 41 sections of the pipe due to “anomalies” after inspections in 2007 and 2012. PHMSA investigators noticed “three repairs to the Affected Pipeline in the area near the Failure site that had been made due to external corrosion” after the 2012 inspection.

Although Line 901 was not extremely old – construction began in 1986 and it went into service in 1991 – Bea pointed to a study of pipe failures in the Gulf of Mexico that he co-authored. Most of those failures happened at about ten years of age.

“I’ll place a bet that when we finally get those results [from the 2012 inspection], we are going to see sections of that pipeline that should not have been allowed to be in operation until 2015,” said Bea, noting a lack of diligence by the operator to responsibly manage risk and the weakness of government oversight.